Baiyear Customized Top Precision Plastic Mold Maker Molding Service Tooling Manufacturer customs service Plastic Transparent Cover Box Case

Service

1: Please Provide your CAD drawings, 2D or 3D drawings, or your ideas,tell us your quantity and requirements. Our engineering team will give you a reasonable analysis plan within 48 hours.

2:Choose the craft, we give you the most competitive quotation.

Choose the manufacturing process you need, then choose from over 70 materials, as well as a range of finishes and certifications. After the two parties reach an agreement, our company will start the project.

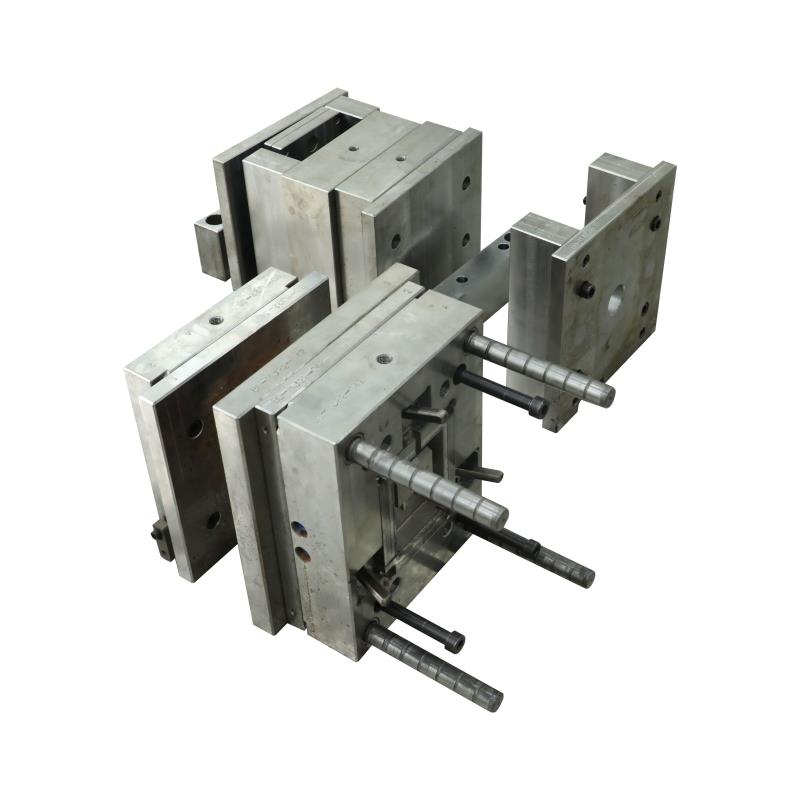

3:Mold design and production, our mold team will make use of numerous mold engraving equipment to make molds, and constantly adjust until it meets quality and customer requirements.

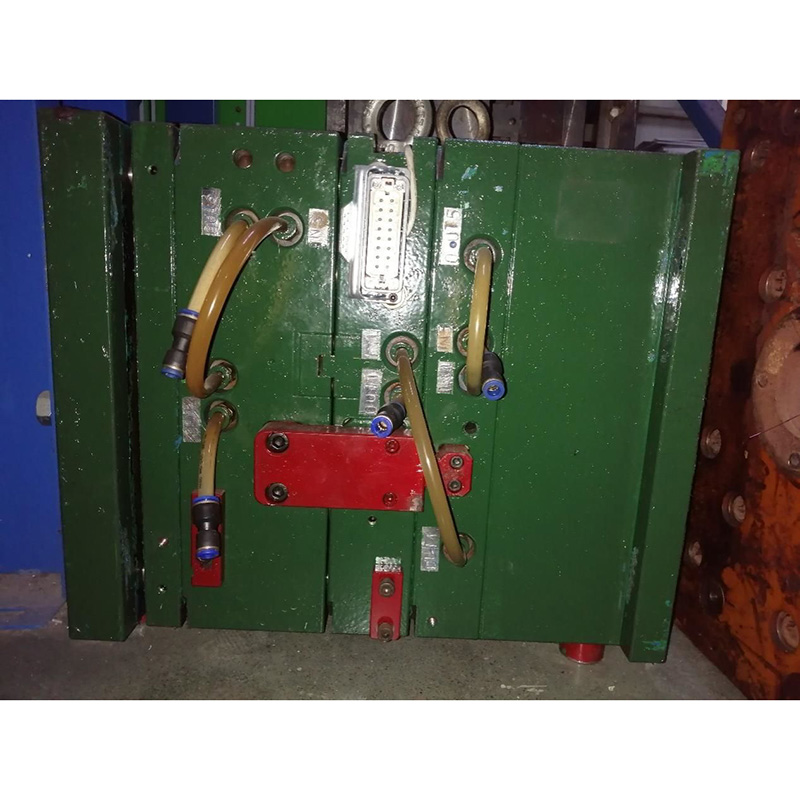

4:After the mold is made, we need to put it into the injection molding machine to process the plastic products. After the high-intensity all-round experiment in the laboratory and the approval of the process department, the plastic parts can be mass-produced.

5:In the process of mass production of plastic parts, our quality department conducts a large number of inspections and tests on the products every day. During the injection molding process, workers will also inspect the products to eliminate defective products.

6:We have powerful automatic equipment, which can complete the assembly of plastic parts with high efficiency and high quality. After the assembly is completed, the relevant personnel of our quality department will strictly inspect the goods.

7:Before the goods leave the factory, we will also conduct a final inspection of the goods, and customers can also conduct video inspections at any time, or other inspection methods, we can meet the reasonable requirements of customers.

What is the order process?

A:Please give us your mold requirements, including drawings, quality requirements, process requirements, material requirements, etc. Our mold engineer will provide detailed analysis and quotation according to your mold requirements. After you are satisfied, we will be at the mold research and development center at the mold research and development center. After molding and testing, after molding, you need your satisfaction, and we will do later work.

Q:What's your warranty?

A:We provide permanent after -sales service, 2 years of quality assurance.

Q:How many mold production equipment do you have?

A:We have 23 mold production equipment with a variety of functions. These devices are relatively advanced recently, which fully meets our mold engineer design and production of various plastic mold molds. We also support video inspection of our factory's strength, video call visits to our equipment, and scale, and you are welcome to visit our factory in person.